Multifunctional bending machine

1.Features of the machine:

BKT25T-250 multifunctional bending machine is our patented product, through years of technical investment and the development of multifunctional sheet metal equipment. The equipment by replacing different mold to achieve diversified workpiece processing, bending mold can process circular triangle, square polygon shape, punching mold can replace punch can reach hundreds of cutting way processing, cutting mold can cut within a certain range of plate, replace bending mold can bend round pipe, square pipe and other profiles. We are able to design different molds for the machine according to customer needs.

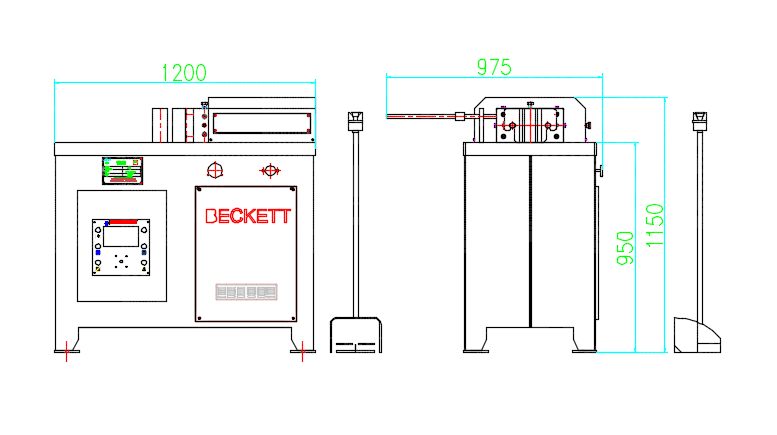

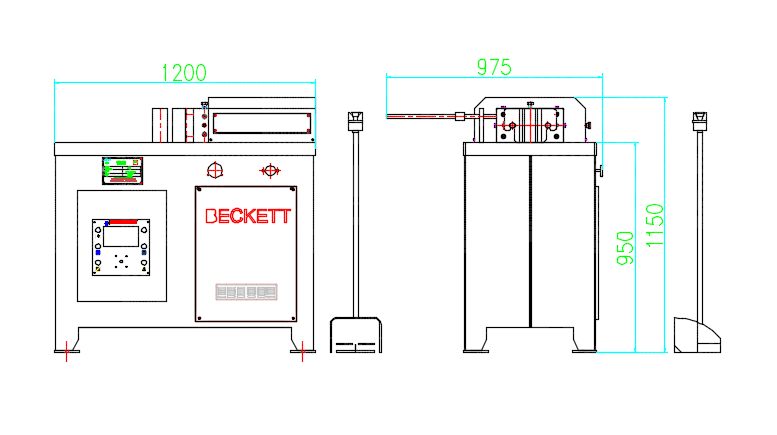

2.Equipment size:

Overall dimensions of the multifunctional bending machine

3.technical parameter:

|

BKT25T-250technical parameter |

|||

|

1 |

working pressure |

Working stength |

250kn |

|

2 |

working speed |

Working speed |

10mm/s |

|

3 |

opening speed |

Return speed |

35mm/s |

|

4 |

Oil cylinder itinerary |

Maximum displacement |

250mm |

|

5 |

repeatability precision |

Repetitivty |

0.05 |

|

6 |

bed dimension |

Bench size |

600mm*1170mm |

|

7 |

bench height |

Working height |

950mm |

|

8 |

control method |

Programming mode |

Manual or Automatic |

|

|

|

|

Safety Double acting hold pedal |

|

|

|

|

Mechanic ally Guided Piston |

|

|

|

|

Piece counter |

|

|

|

|

Pressure regulator |

|

9 |

power of motor |

Engine power |

2.2kw/3HP a1400r/pm |

|

10 |

voltage |

Electric Tension |

220/380V three-phased |

|

11 |

current |

Intensity |

9/5A |

|

12 |

|

Hydraulic pressure |

50 a 215kg/cm2 |

|

13 |

oil pump |

Hydrauic pump |

75litres/minute |

|

14 |

fuel tankage |

Tank Capacity |

35L |

|

15 |

Machine shape size |

Machine dimensions |

1200mm*1000mm*1150mm |

|

16 |

packing measurement |

|

850mm*1300mm*1500mm |

|

17 |

weight |

Weight |

1025kg |

|

18 |

rough weight |

Gross Weight |

1120kg |

|

19 |

volume |

Volume: |

1.46 m3 |

|

20 |

customs code |

HS Code: |

84622990000 |

|

21 |

manner of packing |

Wooden box packaging, suitable for shipping |

Packing included: Wooden pallet NIMF15 and three layer cardboard apt for suitable for sea freight. |

BKT25T-250Multi-function bending machine

Standard parts configuration is as follows (random)

| order number |

name |

name |

remarks |

|

1 |

|

Main engine (including operation console) |

380V50HZ(Special voltage needs to be customized) |

|

2 |

|

Standard propulsion mold |

Contains connecting plates and standard mold seats and a standard propulsion mold,push the mold high:150mm |

|

3 |

|

30°*70H*D70 |

A set of 30° propulsion and fixing molds(Fixed mold height 70mm diameter 70mm),push the mold high:150mm |

|

4 |

|

80°*60H*D40 |

A set of 80° propulsion and fixing molds(Fixed mold height 60mm diameter 40mm),push the mold high:150mm |

|

5 |

|

80°*60H*D22 |

A set of 80° propulsion and fixing molds(Fixed mold height 60mm diameter 22mm),push the mold high:150mm |

|

6 |

|

80°*150H*D70 |

A set of 80° propulsion and fixing molds(Fixed mold height 150mm diameter 70mm),push the mold high:150mm |

|

7 |

|

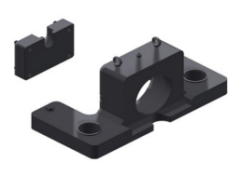

Punch mold |

One set of punch die seat and connecting plate (excluding punch) |

|

8 |

|

Circulating mold |

|

|

9 |

|

Cut the mold |

|

|

10 |

|

Strengthen bending mold |

|

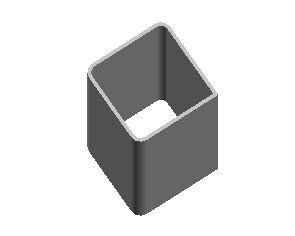

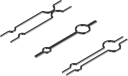

Standard mold

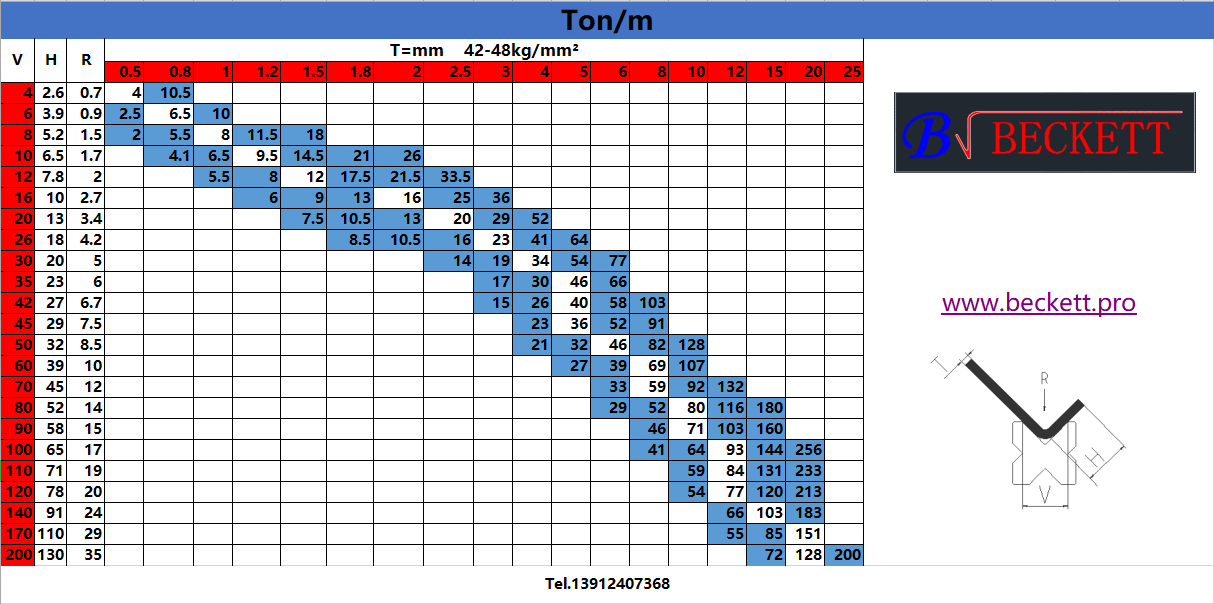

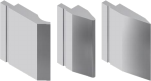

The height of the propulsion standard mold is 150mm. Slot width is V16 V22 V35 V50mm.

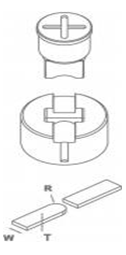

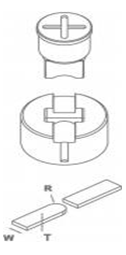

Technical drawing number:BKT25T-250.01

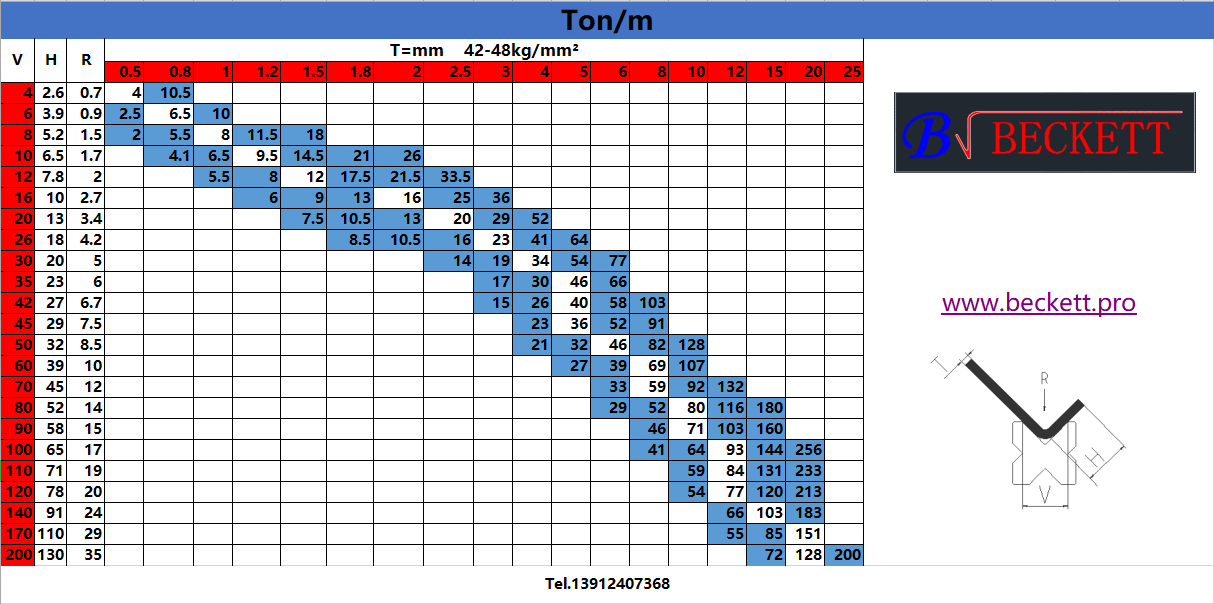

Die bending The standard mold is 150mm high, 4 openings (16,22,35,50mm) and an 80 fixed mold, 100mm high for plate bending ranging from 1mm-12mm. The inner diameter range of the machining workpiece is greater than 70mm. At least 75mm inner diameter.

Scope of reference for processing:

1、 Suitable for slot V16 from 1-3mm sheet

1、 Suitable for slot V16 from 1-3mm sheet

2、 Suitable for slot V22 from 2-4mm sheet

3、 Suitable for slot V35 from 3-6mm sheet

4、 Suitable for slot V50 from 4-8mm sheet.

5、 Bend height: 100mm

6、 Bend thickness of 8mm

The mold is fitted to standard with the machine

The chart is the bend and bend reference table

Standard mold technical parameters and processing examples

|

|

Bend mold:D70 30o |

|

|

|

|

Bend mold:D40 80o |

|

|

|

|

Bend mold:D22 80o |

|

|

|

|

Bend mold:D70 80o |

|

|

Push molds with different openings can be processed up to 15mm. Please contact the manufacturer if a special mold is required.

|

Bend mold:

|

||||

|

|

Technical drawing number: |

|

||

|

long |

wide |

tall |

weight |

|

|

outline dimension |

43mm |

35mm |

200mm |

52kg |

The following molds can be provided separately according to the production requirements

|

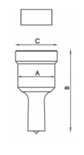

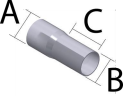

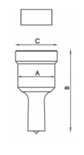

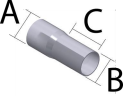

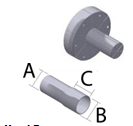

► Standard equipped-O punch

|

mm Ø10-Ø28 Ø29-Ø40 Ø41-Ø43 |

The head specification is Ø 10.12.14.16.18.20.22.24.26.28 29.30.31.32.32.33.34.35.36.37.38.39.40 41-42-43 |

A |

B |

C |

|

39mm |

70mm |

43mm |

|||

|

39mm |

70mm |

43mm |

|||

|

50mm |

70mm |

54mm |

|||

|

For different sizes, please ask the manufacturer |

|||||

|

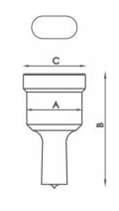

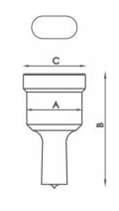

► Standard equipped- O-type bonnet

|

mm Ø10-Ø28 Ø29-Ø40 Ø41-Ø43 |

The head specification is Ø 10.12.14.16.18.20.22.24.26.28 29.30.31.32.32.33.34.35.36.37.38.39.40 41-42-43 |

A |

B |

|

60mm |

32mm |

|||

|

60mm |

32mm |

|||

|

80mm |

32mm |

|||

|

For different sizes, please ask the manufacturer |

||||

|

► Standard equipped-square drift

|

mm*mm 4-28 21-28 29-35 |

The head specification is mm*mm 4.5.6.7.8.9.10.11.12.13.14.15.16.17.18.19.20 21.22.23.24.25.26.27.28 29.30.31.32.33.34.35 |

A |

B |

C |

|

39 |

70 |

43 |

|||

|

39 |

70 |

43 |

|||

|

50 |

70 |

54 |

|||

|

For different sizes, please ask the manufacturer |

|||||

|

► Standard equipped- Square bonnet

|

mm*mm

4-28 21-28 29-35 |

The head specification is mm*mm

4.5.6.7.8.9.10.11.12.13. 20.21.22.23.24.25.26.27.28 29.30.31.32.33.34.35 |

A |

B

|

|

|

60mm |

32mm |

||||

|

60mm |

32mm |

||||

|

80mm |

32mm |

||||

|

For different sizes, please ask the manufacturer |

|||||

|

► Standard equipped-Rectangular head

|

mm*mm 7-9*15 11-15*21 13-20*34 |

The head specification is mm*mm 7*10 7*15 9*13 9*19 11*17 11*23 13*19 15*21 13*25/15*27/17*25/19*30/20*34 |

A |

B |

C |

|

39 |

70 |

43 |

|||

|

39 |

70 |

43 |

|||

|

50 |

70 |

54 |

|||

|

For different sizes, please ask the manufacturer |

|||||

|

► Standard

|

type

n46

n60 |

The head specification is mm*mm

7*10/7*15/9*13/9*19/11*17/11*23/13*19/13*25/15*21 15*27/17*25/19*30/20*34 |

A

|

B |

|

60mm |

32mm |

|||

|

80mm |

32mm |

|||

|

For different sizes, please ask the manufacturer |

||||

|

► Standard equipped-Oval head

|

|

A |

B |

C |

|

|

n28 |

7*10/7*15/7*20/9*13/9*19/11*17/11*23/13*18 |

28mm |

70mm |

31,5mm |

|

|

n40 |

13*31/15*31/17*31/17*40/19*31 |

40m |

70mm |

43.5mm |

|

|

For different sizes, please ask the manufacturer |

|||||

|

► Standard

|

type

n46

n60 |

Available dimensions

|

A |

B |

|

7*10/7*15/7*20/9*13/9*19/11*17/11*23/13*18/13*22

13*2715*20/15*24/15*27/17*22/17*26/19*26/21*27 |

60 |

32 |

||

|

13*31/15*31/17*31/17*40/19*31/19*40/21*31/21*40

|

80 |

32 |

||

|

For different sizes, please ask the manufacturer |

||||

|

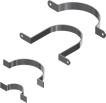

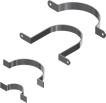

► Standard |

Holder mold 28-40mm 40-50mm |

Yes for the pipe diameter range mm |

|

|

16-28 |

Technical drawing number: |

||

|

28-40 |

Technical drawing number: |

||

|

40-50 |

Technical drawing number: |

||

|

For different sizes, please ask the manufacturer |

|||

|

► Standard

|

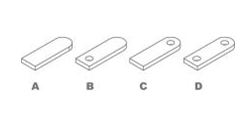

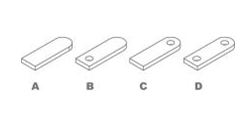

Flat iron flush round head die1# |

model |

Width range |

Technical drawing number |

|

A |

20-35mm |

|

||

|

B |

20-35mm |

|

||

|

C |

20-35mm |

|

||

|

D |

20-35mm |

|

||

|

A |

40-50mm |

|

||

|

B |

40-50mm |

|

||

|

C |

40-50mm |

|

||

|

D |

40-50mm |

|

||

|

|

Contact the manufacturer to confirm the drawings when requiring customization。 Plate material, R (radius), W (width), T (thickness) must be provided when placing an order specify the diameter of the hole in the drawing, in B, C, and D. The R is the length of W, and L Is adjustable. Production capacity: 450 to 600 parts per hour. |

|||

|

► Standard

|

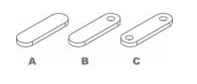

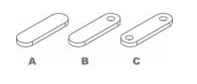

Flat iron flush round head die2# |

Workpiece shape |

Width range |

Technical drawing number: |

|

A |

20-35mm |

|

||

|

B |

20-35mm |

|

||

|

C |

20-35mm |

|

||

|

A |

40-50mm |

|

||

|

B |

40-50mm |

|

||

|

C |

40-50mm |

|

||

|

|

Contact the manufacturer to confirm the drawings when requiring customization. Plate material, R (radius), W (width), T (thickness) must be provided when placing an order specify the diameter of the hole in the drawing, in B, C, and D. The R is the length of W, and L is adjustable. Production capacity: 450 to 600 parts per hour. |

|||

|

Corner R mold |

Available dimensions(mm) |

Technical drawing number |

|

|

R3-16mm |

|

||

|

R16-26 |

|

||

|

R26-32 |

|

||

|

|

|||

|

|

locknut |

Each punch hole diameter is different.Please confirm the size and contact the manufacturer |

|

|

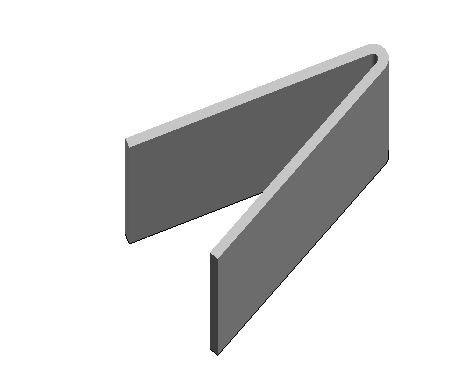

► Standard

|

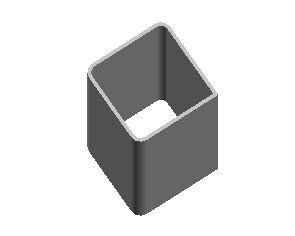

figure number: Ring mold, U-type O workpiece,the biggest characteristic of the mold is that it can process thick plate with a small diameter, with no straight edge end. Consult the manufacturer for other sizes and applications. |

|

|

|

Maximum height of processing |

Processing workpiece thickness |

Extra-mold size |

weight |

|

50mm |

6mm |

90mm |

9.3kg |

|

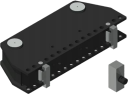

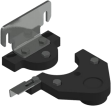

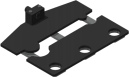

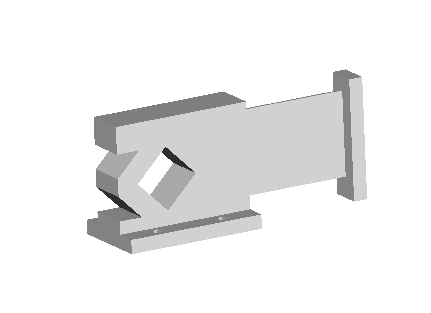

► Standard |

figure number: Flat steel cut the mold, 135mm and the maximum thickness of 14mm steel. |

|

|

The shear plate is wide |

Cut plate thick |

weight |

|

135mm |

14mm |

23kg |

|

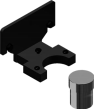

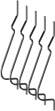

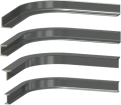

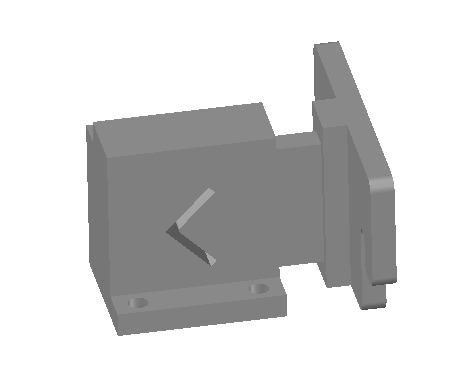

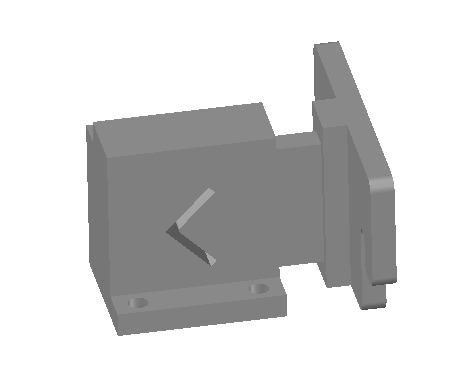

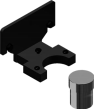

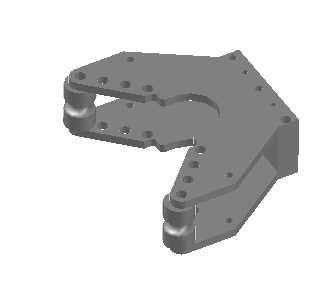

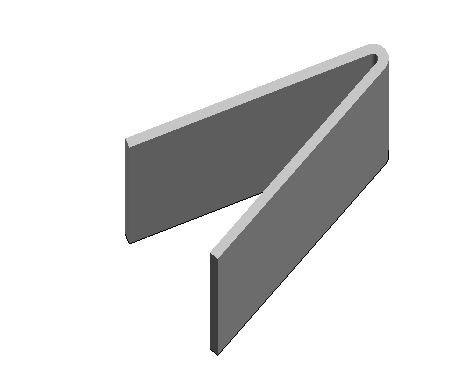

► Standard |

Reanced bent bracket for bending or folding special workpieces |

|

|

Folding height |

weight |

|

|

150mm |

14kg |

|

|

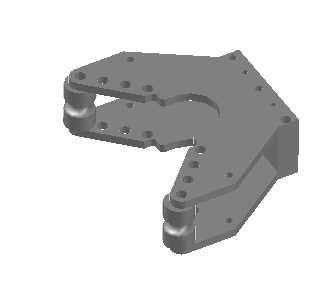

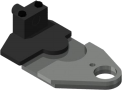

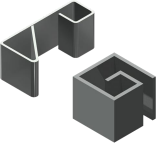

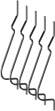

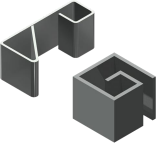

► Standard

equipped- Mold 1

|

Technical drawing number:

Mold height:150mm

Weight:3.2kg

|

|

|

► Standard

equipped- Mold 2

|

Technical drawing number:

Mold height:150mm

Weight:2.3kg |

|

|

► Standard equipped- Mold 3

|

Technical drawing number:

Mold height:150mm

Weight:2.7kg

|

|

以下模具為選配

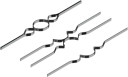

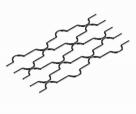

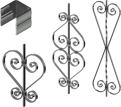

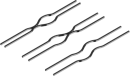

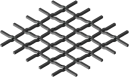

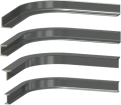

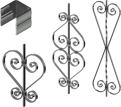

► Select equipped-molding mold 01

|

The mold forms cold forged railings for grilles, gates, fences, handrails, etc. Consult the manufacturer for other shape or capacity requirements. |

|

|

|

Width: Customer to figure customization |

Height: the customer to customize |

Mold length: the customer to customize |

weight |

|

20mm |

4 5 6 8mm |

656mm |

21kg |

|

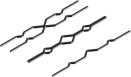

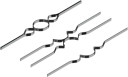

► Select equipped-Rail molding mold 02

|

References: 140-16-01-00004

The mold forms cold forged railings for grilles, gates, fences, handrails, etc. |

|

|

Square |

Mold length |

weight |

|

5、6、8、10、12、14、16、 |

600mm |

20.5kg |

The mold is a small semicircle, which can process flat iron, square pipe, round pipe and other profiles, and the advantage is that the processed workpiece can be very close to the mold radian.

Consult the m

|

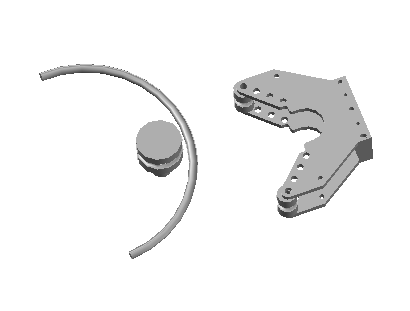

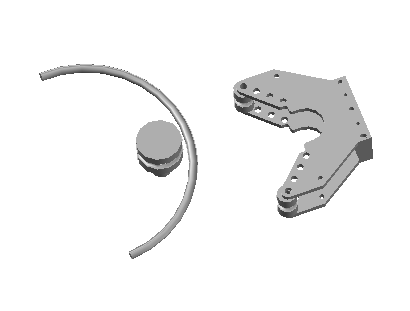

► Select equipped-Radius R200 bending mold 03

|

|

||

|

|

Maximum pipeline capacity |

minimum diameter |

Maximum diameter |

|

40mm或11/2’’ |

80x80mm或3’’ |

300mm |

There is no maximum |

anufacturer for other shape or capacity requirements

|

► Select equipped-Rail molding mold 04

|

Technical drawing number:

The mold forms cold forged railings for grilles, gates, fences, handrails, etc. |

|

|

|

width |

altitude |

Mold length |

weight |

|

20mm |

4 5 6 8mm |

650mm |

19 5kg |

|

► Select equipped-Rail molding mold 05

|

Technical drawing number:

The mold forms cold forged railings for grilles, gates, fences, handrails, etc. |

|

|

Flat strip size |

Mold length |

weight |

|

5,6,8,10,12mm |

522mm |

22kg |

|

► Select equipped-Rail molding mold 06

|

Technical drawing number:

The mold forms a cold forged railing-shaped parts grill, the so-called "belly top rail". |

|

|

Flat strip size |

Mold length |

weight |

|

12mm |

1165mm |

50kg |

|

|

||

|

► Select equipped-Rail molding mold 07

|

Technical drawing number:

The mold forms cold forged railings for grilles, gates, fences, handrails, etc. |

|

|

Flat strip size |

Mold length |

weight |

|

6,8,10,12mm |

760mm |

32.5kg |

|

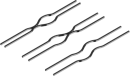

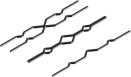

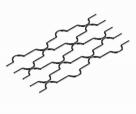

► Select equipped-Distorted forming mold 08

|

Technical drawing number: Mold bends metal plates, flats or squares for good woven twist effect. It was used to make fences and grills. For flat bars ranging from 6,12, and 14mm. Consult the manufacturer for other shape or capacity requirements. |

|

|

process capability |

specifications |

weight |

|

square14mm |

2x40mm sheetmetal |

18kg |

|

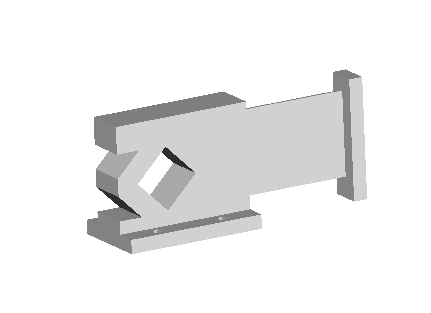

► Select equipped-The mold is to bend the square or PP200 rectangular tube 09

|

Technical drawing number: A tool for bending a square tube or rod to a given or certain extent. Drawings or samples.

|

|

|

Maximum bending Aangle of greatest flexion |

weight |

|

|

30mmo11/4“x3mm thickness 120o-150o |

110kg |

|

|

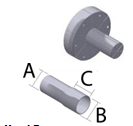

Basic molds, to modify the ends of the tubes, for their assembly. You can do various shapes and flaps to suit customer needs. |

||

|

|

Technical drawing number: |

|

||||

|

|

||||||

|

|

Technical drawing number: |

|

||||

|

|

||||||

|

|

Technical drawing number: |

|

||||

|

Maximum outer diameter AØ |

Minimum outer diameter BØ |

Length C |

reference material |

explain |

||

|

16mm |

10mm |

76mm |

|

Tube shrinkage range 16-10 length C 76mm |

||

|

19mm |

13mm |

76mm |

|

Tube shrinkage range 19-13length C 76mm |

||

|

22mm |

16mm |

76mm |

|

Tube shrinkage range 22-16length C 76mm |

||

|

25mm |

19mm |

76mm |

|

Tube shrinkage range 25-19length C 76mm |

||

|

28mm |

22mm |

76mm |

|

Tube shrinkage range 28-22length C 76mm |

||

|

31mm |

25mm |

76mm |

|

Tube shrinkage range 31-25length C 76mm |

||

|

35mm |

29mm |

76mm |

|

Tube shrinkage range 35-29length C 76mm |

||

|

38mm |

32mm |

76mm |

|

Tube shrinkage range 38-32length C 76mm |

||

|

42mm |

36mm |

76mm |

|

Tube shrinkage range 42-36length C 76mm |

||

|

45mm |

39mm |

76mm |

|

Tube shrinkage range 45-39length C 76mm |

||

|

48mm |

42mm |

76mm |

|

Tube shrinkage range 48-42length C 76mm |

||

|

51mm |

45mm |

76mm |

|

Tube shrinkage range 51-45length C 76mm |

||

|

54mm |

48mm |

76mm |

|

Tube shrinkage range 54-48length C 76mm |

||

|

57mm |

51mm |

76mm |

|

Tube shrinkage range 57-51length C 76mm |

||

|

60mm |

54mm |

76mm |

|

Tube shrinkage range 60-54length C 76mm |

||

|

63mm |

57mm |

76mm |

|

Tube shrinkage range 63-57length C 76mm |

||

|

66mm |

60mm |

76mm |

|

Tube shrinkage range 66-60length C 76mm |

||

|

69mm |

63mm |

76mm |

|

Tube shrinkage range 69-63length C 76mm |

||

|

73mm |

67mm |

76mm |

|

Tube shrinkage range 73-67length C 76mm |

||

|

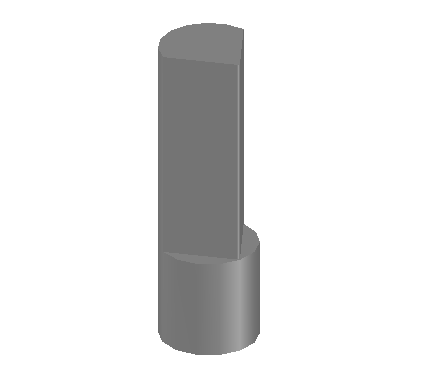

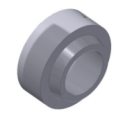

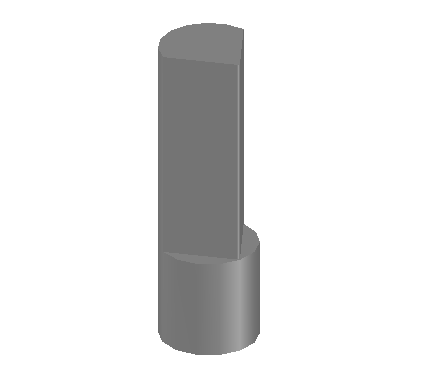

► Select equipped-PP200expansion mandrel rod 13

|

Technical drawing number: The attachment is designed to shape the tube end to enlarge the tube end. This accessory is used for all tube sizes, that is, there is no need to buy multiple as it fits into all diameters. |

|

|

|

|

► Select equipped-14

|

Technical drawing number: The attachment is designed to shape the tube end to enlarge the tube end. This accessory is used for all tube sizes, that is, there is no need to buy multiple as it fits into all diameters. |

|

|

|

|

► Select equipped-PP200 Tube expansion clip 15

|

Technical drawing number:

The attachment is designed to shape the tube end to enlarge the tube end.

See the following table |

|

AØ |

maximumBØ |

length |

Technical drawing number |

explain |

|

|

22mm |

28mm |

40mm |

|

Pipe expansion range22-28 |

Maximum length 40mm |

|

25mm |

31mm |

40mm |

|

Pipe expansion range25-31 |

|

|

28mm |

34mm |

50mm |

|

Pipe expansion range28-34 |

Maximum length 50mm |

|

31mm |

37mm |

60mm |

|

Pipe expansion range31-37 |

Maximum length 60mm |

|

35mm |

41mm |

60mm |

|

Pipe expansion range35-41 |

Maximum length60mm |

|

38mm |

44mm |

65mm |

|

Pipe expansion range38-44 |

Maximum length65mm |

|

41mm |

47mm |

65mm |

|

Pipe expansion range41-47 |

Maximum length65mm |

|

44mm |

50mm |

80mm |

|

Pipe expansion range44-50 |

Maximum length80mm |

|

47mm |

53mm |

80mm |

|

Pipe expansion range47-53 |

Maximum length80mm |

|

51mm |

57mm |

80mm |

|

Pipe expansion range51-57 |

Maximum length80mm |

|

54mm |

60mm |

80mm |

|

Pipe expansion range54-60 |

Maximum length80mm |

|

60mm |

66mm |

80mm |

|

Pipe expansion range60-66 |

Maximum length80mm· |

|

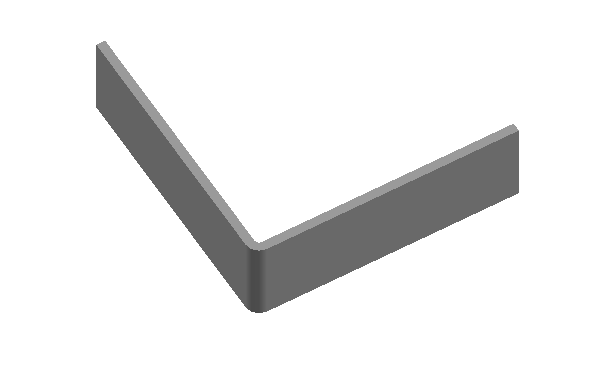

► Select equipped-Flat (bending) mold 16

|

Technical drawing number: Tool for bending straight profiles or parts that can be adjusted to different capacities.

|

|

|

maximum altitude |

weight |

|

|

H160mm |

72kg |

|

|

► Select equipped-Bend special profile mold 17

|

Technical drawing number: Bend or fold different profiles such as U, T angles etc... with other specific radii and angles. Contact the manufacturer for the technical drawings or samples. |

|

|

► Select equipped-Rail molding mold 18

|

Technical drawing number: The mold forms cold forged railings for grilles, gates, fences, handrails, etc. Consult the manufacturer for other shape or capacity requirements. |

|

|

square |

|

weight |

|

12mm*12mm |

90mm |

11kg |

|

► Select equipped-Cping molding mold 19

|

Technical drawing number: The mold forms various card hoops. This tool is manufactured according to the user's needs. Contact the manufacturer for the technical drawings or samples |

|

|

maximum altitude |

||

|

100mm*4mm |

||

|

► Select equipped-Forming mold adapter fold punch to bend special small size or fold to 30o 20

|

Technical drawing number: Cping forming mold for making clips to connect different forged rods without welding. |

|

|

process capability |

weight |

|

|

25mm*5mm |

9kg |

|

|

|

||

|

► Select equipped-Angle steel cutting die 21

|

Technical drawing number: For cutting off the 70 * 70 angle iron |

|

|

process capability |

weight |

|

|

70*70 |

|

|

|

► Select equipped-Square pipe cut off die 22

|

Technical drawing number: To cut off the square pipe within 70 * 70 |

|

|

process capability |

weight |

|

|

70*70 |

|

|

|

► Select equipped-Round-tube bending die 23

|

|

► Select equipped- 24

|

Technical drawing number: |

Standard model: |

|

► Select equipped- 25 |

Technical drawing number:

The mold is mounted on the frame and can be adjusted. Each different specification requires the same mold. |

Standard models: 18、22、38、42、48 |

|

► Select equipped- 26

|

Technical drawing number: The mold is mounted on the workbench, each different specification of the round pipe need the same die. |

Standard models: 18、22、38、42、48 |

|

outline dimension |

weight |

|

1、機器特點:

BKT25T-250多功能折彎機是我們的專利產品,通過多年的技術投入和多功能鈑金設備的開發。該設備通過更換不同模具實現工件多樣化加工,折彎模具可加工圓形三角形、方形多邊形,沖孔模具可替代沖床可達到數百種切割方式加工,切割模具可在一定范圍內切割板材,替代折彎模具可彎圓管、方管等型材。我們可以根據客戶需求為機器設計不同的模具。

2.設備尺寸:

多功能折彎機外形尺寸

3.技術參數:

|

BKT25T-250技術參數 |

|||

|

1 |

工作壓力 |

工作強度 |

250kn |

|

2 |

工作速度 |

工作速度 |

10毫米/秒 |

|

3 |

開啟速度 |

回程速度 |

35毫米/秒 |

|

4 |

油缸行程 |

最大排量 |

250mm |

|

5 |

重復精度 |

重復性 |

0.05 |

|

6 |

床尺寸 |

工作臺尺寸 |

600mm*1170mm |

|

7 |

工作臺高度 |

工作高度 |

950mm |

|

8 |

控制方法 |

編程模式 |

手動或自動 |

|

|

|

|

安全 雙作用腳踏板 |

|

|

|

|

機械同盟導向活塞 |

|

|

|

|

計件器 |

|

|

|

|

壓力調節器 |

|

9 |

電機功率 |

發動機功率 |

2.2kw/3HP a1400r/pm |

|

10 |

電壓 |

電動張力 |

220/380V 三相 |

|

11 |

當前的 |

強度 |

9/5A |

|

12 |

|

液壓 |

50一215kg/cm2 |

|

13 |

油泵 |

液壓泵 |

75升/分鐘 |

|

14 |

油箱 |

油箱容量 |

35L |

|

15 |

機器外形尺寸 |

機器尺寸 |

1200mm*1000mm*1150mm |

|

16 |

包裝測量 |

|

850mm*1300mm*1500mm |

|

17 |

重量 |

重量 |

1025公斤 |

|

18 |

粗重 |

總重量 |

1120公斤 |

|

19 |

體積 |

體積: |

1.46 立方米 |

|

20 |

海關編碼 |

HS編碼: |

84622990000 |

|

21 |

包裝方式 |

木箱包裝,適合海運 |

包裝包括:木制托盤 NIMF15 和適合海運的三層紙板。 |

BKT25T-250多功能折彎機

標準件配置如下(隨機)

| 訂單號 |

姓名 |

姓名 |

評論 |

|

1 |

|

主機(含操作臺) |

380V50HZ(特殊電壓需定制) |

|

2 |

|

標準推進模具 |

包含連接板和標準模座和標準推進模具,推模高度:150mm |

|

3 |

|

30°*70H*D70 |

一組30°推進和固定模具(固定模具高度70mm直徑70mm),推模高度:150mm |

|

4 |

|

80°*60H*D40 |

一組80°推進和固定模具(固定模具高度60mm直徑40mm),推模高度:150mm |

|

5 |

|

80°*60H*D22 |

一套80°推進和固定模具(固定模具高度60mm直徑22mm),推模高度:150mm |

|

6 |

|

80°*150H*D70 |

一套80°推進和固定模具(固定模具高度150mm直徑70mm),推模高度:150mm |

|

7 |

|

沖床模具 |

沖頭模座及連接板一套(不含沖頭) |

|

8 |

|

循環模具 |

|

|

9 |

|

剪開模具 |

|

|

10 |

|

加強折彎模具 |

|

標準模具

推進標準模具的高度為150mm。槽寬為 V16 V22 V35 V50mm。

技術圖號:BKT25T-250.01

模具折彎標準模具為150mm高,4個開口(16、22、35、50mm)和一個80固定模具,100mm高,用于1mm-12mm的板材彎曲。加工工件的內徑范圍大于70mm。至少 75mm 內徑。

加工參考范圍:

1、 適用于1-3mm板材的槽V16

1、 適用于1-3mm板材的槽V16

2、 適用于2-4mm板材的槽V22

3、 適用于3-6mm板材的槽V35

4、 適用于4-8mm板材的槽V50 .

5、折彎高度:100mm

6、折彎厚度8mm

模具與機器符合標準

圖表為折彎及折彎參考表

標準模具技術參數及加工實例

|

|

折彎模具:D70 30o |

|

|

|

|

折彎模具:D40 80o |

|

|

|

|

折彎模具:D22 80o |

|

|

|

|

折彎模具:D70 80o |

|

|

不同開口的推模最大可加工15mm。如需特殊模具,請與制造商聯系。

|

折彎模具:

|

||||

|

|

技術圖號: |

|

||

|

長 |

寬的 |

高 |

重量 |

|

|

外形尺寸 |

43毫米 |

35mm |

200mm |

52公斤 |

可根據生產要求單獨提供以下模具

|

►標準配備-O 沖頭

|

毫米 Ø 10-Ø 28 Ø 29-Ø 40 Ø 41-Ø 43 |

頭部規格為Ø 10.12.14.16.18.20.22.24.26.28 29.30.31.32.32.33.34.35.36.37.38.39.40 41-42-43 |

一個 |

乙 |

C |

|

39毫米 |

70mm |

43毫米 |

|||

|

39毫米 |

70mm |

43毫米 |

|||

|

50mm |

70mm |

54毫米 |

|||

|

如需不同尺寸,請咨詢制造商 |

|||||

|

►標準 配備- O 型 閥蓋

|

毫米 Ø 10-Ø 28 Ø 29-Ø 40 Ø 41-Ø 43 |

頭部規格為Ø 10.12.14.16.18.20.22.24.26.28 29.30.31.32.32.33.34.35.36.37.38.39.40 41-42-43 |

一個 |

乙 |

|

60mm |

32mm |

|||

|

60mm |

32mm |

|||

|

80mm |

32mm |

|||

|

如需不同尺寸,請咨詢制造商 |

||||

|

►標準 配備方形漂移

|

毫米*毫米 4-28 21-28 29-35 |

頭部規格為mm*mm 4.5.6.7.8.9.10.11.12.13.14.15.16.17.18.19.20 21.22.23.24.25.26.27.28 29.30.31.32.33.34.35 |

一個 |

乙 |

C |

|

39 |

70 |

43 |

|||

|

39 |

70 |

43 |

|||

|

50 |

70 |

54 |

|||

|

如需不同尺寸,請咨詢制造商 |

|||||

|

►標準 配備- 方形閥蓋

|

毫米*毫米

4-28 21-28 29-35 |

頭部規格為mm*mm

4.5.6.7.8.9.10.11.12.13。 20.21.22.23.24.25.26.27.28 29.30.31.32.33.34.35 |

一個 |

乙

|

|

|

60mm |

32mm |

||||

|

60mm |

32mm |

||||

|

80mm |

32mm |

||||

|

如需不同尺寸,請咨詢制造商 |

|||||

|

►標準 配備-矩形頭

|

毫米*毫米 7-9*15 11-15*21 13-20*34 |

頭部規格為mm*mm 7 *10 7 *15 9 *13 9 *19 11 *17 11 *23 13 *19 15 *21 13 *25/15 *27/17 *25/19 *30/20 *34 |

一個 |

乙 |

C |

|

39 |

70 |

43 |

|||

|

39 |

70 |

43 |

|||

|

50 |

70 |

54 |

|||

|

如需不同尺寸,請咨詢制造商 |

|||||

|

►標準

|

類型

n46

n60 |

頭部規格為mm*mm

7 *10/7 *15/9 *13/9 *19/11 *17/11 *23/13 *19/13 *25/15 *21 15 *27/17 *25/19 *30/20 *34 |

一個

|

乙 |

|

60mm |

32mm |

|||

|

80mm |

32mm |

|||

|

如需不同尺寸,請咨詢制造商 |

||||

|

►標準 配備-橢圓頭

|

|

一個 |

乙 |

C |

|

|

n28 |

7 *10/7 *15/7 *20/9 *13/9 *19/11 *17/11 *23/13 *18 |

28mm |

70mm |

31,5mm |

|

|

n40 |

13 *31/15 *31/17 *31/17 *40/19 *31 |

40m |

70mm |

43.5毫米 |

|

|

如需不同尺寸,請咨詢制造商 |

|||||

|

►標準

|

類型

n46

n60 |

可用尺寸

|

一個 |

乙 |

|

7 * 10/7 * 15/7 * 20/9 * 13/9 * 19/11 * 17/11 * 23/13 * 18/13 * 22

13 * 2715 * 20/15 * 24/15 * 27/17 * 22/17 * 26/19 * 26/21 * 27 |

60 |

32 |

||

|

13 * 31/15 * 31/17 * 31/17 * 40/19 * 31/19 * 40/21 * 31/21 * 40

|

80 |

32 |

||

|

如需不同尺寸,請咨詢制造商 |

||||

|

►標準 |

支架模具 28-40mm 40-50mm |

是的,適用于管徑范圍 mm |

|

|

16-28 |

技術圖紙編號: |

||

|

28-40 |

技術圖紙編號: |

||

|

40-50 |

技術圖紙編號: |

||

|

如需不同尺寸,請咨詢制造商 |

|||

|

►標準

|

扁鐵平頭圓頭模具1# |

模型 |

寬度范圍 |

技術圖紙編號 |

|

一個 |

20 -35mm |

|

||

|

乙 |

20 -35mm |

|

||

|

C |

20 -35mm |

|

||

|

D |

20 -35mm |

|

||

|

一個 |

40 -50mm |

|

||

|

乙 |

40 -50mm |

|

||

|

C |

40 -50mm |

|

||

|

D |

40 -50mm |

|

||

|

|

需要定制時聯系廠家確認圖紙。 板料,R(半徑),W(寬度),T(厚度)下單時必須提供圖紙指定孔的直徑,在B,C,D中。R是W的長度, L是可調的。 生產能力:每小時450至600個零件。 |

|||

|

►標準

|

扁鐵平頭圓頭模具2# |

工件形狀 |

寬度范圍 |

技術圖紙編號: |

|

一個 |

20-35mm |

|

||

|

乙 |

20-35mm |

|

||

|

C |

20-35mm |

|

||

|

一個 |

40-50mm |

|

||

|

乙 |

40-50mm |

|

||

|

C |

40-50mm |

|

||

|

|

需要定制時聯系廠家確認圖紙。 板料,R(半徑),W(寬度),T(厚度)下單時必須提供圖紙指定孔的直徑,在B,C,D中。R是W的長度, L是可調的。 生產能力:每小時450至600個零件。 |

|||

|

角R模具 |

可用尺寸(mm) |

技術圖紙編號 |

|

|

R3-16mm |

|

||

|

R16-26 |

|

||

|

R26-32 |

|

||

|

|

|||

|

|

鎖緊螺母 |

每個沖孔直徑不同。請確認尺寸并聯系制造商 |

|

|

►標準

|

圖號: 環形模具,U型O型工件,該模具最大的特點是可以加工小直徑的厚板,沒有直邊端。 有關其他尺寸和應用,請咨詢制造商。 |

|

|

|

最大加工高度 |

加工工件厚度 |

模外尺寸 |

重量 |

|

50mm |

6mm |

9 0mm |

9 .3公斤 |

|

►標準 |

圖號: 扁鋼切割模具,135mm和14mm鋼的最大厚度。 |

|

|

剪切板很寬 |

切板厚 |

重量 |

|

1 35mm |

1 4mm |

23公斤 |

|

►標準 |

用于彎曲或折疊特殊工件的 Reancered 彎曲支架 |

|

|

折疊高度 |

重量 |

|

|

150mm |

14公斤 |

|

|

►標準

配備-模具1

|

技術圖紙編號:

模具高度:150mm

重量:3 .2公斤

|

|

|

►標準

配備-模具2

|

技術圖紙編號:

模具高度:150mm

重量:2.3公斤 |

|

|

►標準 配備- 模具 3

|

技術圖紙編號:

模具高度:150mm

重量:2.7kg

|

|

模具為選配

►選擇配套成型模具 01

|

該模具形成用于格柵、大門、圍欄、扶手等的冷鍛欄桿。 有關其他形狀或容量要求,請咨詢制造商。 |

|

|

|

寬度:客戶來圖定制 |

高度:客戶定制 |

模具長度:客戶定制 |

重量 |

|

20mm |

4 5 6 8mm |

656毫米 |

21公斤 |

|

► 選擇配備-軌道成型模具02

|

參考文獻:140-16-01-00004

該模具形成用于格柵、大門、圍欄、扶手等的冷鍛欄桿。 |

|

|

正方形 |

模具長度 |

重量 |

|

5、6、8、10、12、14、16、18毫米 |

600mm |

20 .5公斤 |

模具為小半圓,可加工扁鐵、方管、圓管等型材,優點是加工工件可以非常接近模具弧度。

咨詢米

|

► 選擇配備-Radius R200折彎模具03

|

|

||

|

|

最大管道容量 |

最小直徑 |

最大直徑 |

|

40mm或11/2'' |

80x80mm或3'' |

300mm |

沒有最大值 |

其他形狀或容量要求的制造商

|

► 選擇配備-軌道成型模具04

|

技術圖紙編號:

該模具形成用于格柵、大門、圍欄、扶手等的冷鍛欄桿。 |

|

|

|

寬度 |

高度 |

模具長度 |

重量 |

|

20mm |

4 5 6 8mm |

650mm |

19 5公斤 |

|

► 選擇配備-導軌成型模具05

|

技術圖紙編號:

該模具形成用于格柵、大門、圍欄、扶手等的冷鍛欄桿。 |

|

|

扁條尺寸 |

模具長度 |

重量 |

|

5,6,8,10,12mm |

522mm |

22公斤 |

|

► 選擇配備-軌道成型模具 06

|

技術圖紙編號:

該模具形成冷鍛欄桿形零件格柵,即所謂的“腹頂欄桿”。 |

|

|

扁條尺寸 |

模具長度 |

重量 |

|

12mm |

1165毫米 |

50公斤 |

|

|

||

|

►選擇配備-導軌成型模具 07

|

技術圖紙編號:

該模具形成用于格柵、大門、圍欄、扶手等的冷鍛欄桿。 |

|

|

扁條尺寸 |

模具長度 |

重量 |

|

6,8,10,12mm |

760mm |

32 .5公斤 |

|

►選擇配備的-變形成型模具08

|

技術圖紙編號: 模具彎曲金屬板、平面或正方形以獲得良好的編織扭曲效果。它被用來制作柵欄和烤架。適用于 6,12 和 14 毫米的扁鋼。 有關其他形狀或容量要求,請咨詢制造商。 |

|

|

制程能力 |

規格 |

重量 |

|

方形14mm |

2x40mm 鈑金 |

18公斤 |

|

► 選配-模具是彎方管或PP200矩形管09

|

技術圖紙編號: 將方管或方棒彎曲到給定或一定程度的工具。圖紙或樣品。

|

|

|

最大彎曲最大彎曲 角度 |

重量 |

|

|

30mmo11/4“x3mm 厚度 120o-150o |

110公斤 |

|

|

基本模具,用于修改管子的末端,用于組裝。您可以做各種形狀和襟翼以滿足客戶的需求。 |

||

|

|

技術圖號: |

|

||||

|

|

||||||

|

|

技術圖紙編號: |

|

||||

|

|

||||||

|

|

技術圖號: |

|

||||

|

最大外徑 A Ø |

最小外徑 B Ø |

長度 C |

參考資料 |

解釋 |

||

|

16mm |

10mm |

76毫米 |

|

縮管范圍16-10 長度C 76mm |

||

|

19mm |

13mm |

76毫米 |

|

縮管范圍19-13長度C 76mm |

||

|

22mm |

16mm |

76毫米 |

|

管收縮范圍22-16長度C 76mm |

||

|

25mm |

19mm |

76毫米 |

|

管收縮范圍25-19長度C 76mm |

||

|

28mm |

22mm |

76毫米 |

|

縮管范圍28-22長度C 76mm |

||

|

31mm |

25mm |

76毫米 |

|

縮管范圍31-25長度 C 76mm |

||

|

35mm |

29毫米 |

76毫米 |

|

縮管范圍35-29長度C 76mm |

||

|

38mm |

32mm |

76毫米 |

|

縮管范圍38-32長度C 76mm |

||

|

42毫米 |

36mm |

76毫米 |

|

管收縮范圍42-36長度C 76mm |

||

|

45毫米 |

39毫米 |

76毫米 |

|

縮管范圍45-39長度C 76mm |

||

|

48mm |

42毫米 |

76毫米 |

|

管收縮范圍48-42長度C 76mm |

||

|

51毫米 |

45毫米 |

76毫米 |

|

縮管范圍51-45長度C 76mm |

||

|

54毫米 |

48mm |

76毫米 |

|

縮管范圍54-48長度C 76mm |

||

|

57mm |

51毫米 |

76毫米 |

|

縮管范圍57-51長度C 76mm |

||

|

60mm |

54毫米 |

76毫米 |

|

縮管范圍60-54長度C 76mm |

||

|

63毫米 |

57mm |

76毫米 |

|

縮管范圍63-57長度C 76mm |

||

|

66毫米 |

60mm |

76毫米 |

|

縮管范圍66-60長度C 76mm |

||

|

69毫米 |

63毫米 |

76毫米 |

|

縮管范圍69-63長度C 76mm |

||

|

73毫米 |

67毫米 |

76毫米 |

|

管收縮范圍73-67長度C 76mm |

||

|

► 選擇配備的-PP200膨脹芯棒 13

|

技術圖紙編號: 附件設計用于塑造管端以擴大管端。 該配件適用于所有管尺寸,也就是說,無需購買多個,因為它適合所有直徑。 |

|

|

|

|

► 選擇裝備-14

|

技術圖紙編號: 附件設計用于塑造管端以擴大管端。 該配件適用于所有管尺寸,也就是說,無需購買多個,因為它適合所有直徑。 |

|

|

|

|

► 選擇配備的-PP200擴管夾 15

|

技術圖紙編號:

附件設計用于塑造管端以擴大管端。需要根據每根管子的初始直徑和我們想要達到的最終直徑

見下表 |

|

Ø |

最大BØ |

長度 |

技術圖紙編號 |

解釋 |

|

|

22mm |

28mm |

40mm |

|

擴管范圍22-28 |

最大長度40mm |

|

25mm |

31mm |

40mm |

|

擴管范圍25-31 |

|

|

28mm |

34mm |

50mm |

|

擴管范圍28-34 |

最大長度50mm |

|

31mm |

37mm |

60mm |

|

擴管范圍31-3 7 |

最大長度60mm |

|

35mm |

41毫米 |

60mm |

|

擴管范圍35-41 |

最大長度60mm |

|

38mm |

44毫米 |

65毫米 |

|

擴管范圍38-44 |

最大長度65mm |

|

41毫米 |

47毫米 |

65毫米 |

|

擴管范圍41-47 |

最大長度65mm |

|

44毫米 |

50mm |

80mm |

|

擴管范圍44-50 |

最大長度80mm |

|

47毫米 |

53毫米 |

80mm |

|

擴管范圍47-53 |

最大長度80mm |

|

51毫米 |

57mm |

80mm |

|

擴管范圍51-57 |

最大長度80mm |

|

54毫米 |

60mm |

80mm |

|

擴管范圍54-60 |

最大長度80mm |

|

60mm |

66毫米 |

80mm |

|

擴管范圍60-66 |

最大長度80mm · |

|

► 選擇配備的-平(彎)模 16

|

技術圖紙編號: 用于彎曲直線型材或零件的工具,可根據不同的能力進行調整。

|

|

|

最高海拔 |

重量 |

|

|

H1 60mm |

72公斤 |

|

|

►選擇配備-Bend 特殊型材模具 17

|

技術圖紙編號: 用其他特定的半徑和角度彎曲或折疊不同的輪廓,例如 U、T 角等。 聯系制造商索取技術圖紙或樣品。 |

|

|

► 選擇配備-導軌成型模具 18

|

技術圖紙編號: 該模具形成用于格柵、大門、圍欄、扶手等的冷鍛欄桿。 有關其他形狀或容量要求,請咨詢制造商。 |

|

|

正方形 |

|

重量 |

|

12毫米* 12毫米 |

90mm |

11公斤 |

|

► 選擇配備的-Cping成型模具 19

|

技術圖紙編號: 模具形成各種卡箍。該工具是根據用戶的需要制造的。 聯系制造商索取技術圖紙或樣品 |

|

|

最高海拔 |

||

|

100毫米*4毫米 |

||

|

► 選擇配備的成型模具適配器折疊沖頭彎曲特殊的小尺寸或折疊到 30o 20

|

技術圖紙編號: Cping成型模具,用于制作夾子以連接不同的鍛造棒材,無需焊接。 |

|

|

制程能力 |

重量 |

|

|

25毫米*5毫米 |

9公斤 |

|

|

|

||

|

► 選擇配備的-角鋼切割模 21

|

技術圖紙編號: 用于切斷70*70角鐵 |

|

|

制程能力 |

重量 |

|

|

70*70 |

|

|

|

► 選擇配備的方管切斷模 22

|

技術圖紙編號: 切斷70*70以內的方管 |

|

|

制程能力 |

重量 |

|

|

70*70 |

|

|

|

►選擇配備的圓管彎曲模 23

|

|

►選擇裝備 - 24

|

技術圖紙編號: |

標準型號: |

|

►選擇裝備 - 25 |

技術圖紙編號:

模具安裝在框架上,可以調整。每個不同的規格都需要相同的模具。 |

標準型號:18、22、38、42、48 _ _ _ _ _ |

|

►選擇裝備 - 26

|

技術圖紙編號: 模具安裝在工作臺上,每個不同規格的圓管都需要同一個模具。 |

標準型號:18、22、38、42、48 _ _ _ _ _ |

|

外形尺寸 |

重量 |

|

LOCATION:

LOCATION:

150mm

150mm M75*85*63

M75*85*63 Bend mold:M80*85*80

Bend mold:M80*85*80

150mm

150mm M75*85*63

M75*85*63 折彎模具:M80*85*80

折彎模具:M80*85*80